FAQ

Frequently Asked Questions

What are the biggest advantages of VIDALCO Prefab Modules?

- 100% machine prefabricated underfloor heating/cooling.

- Machine can be controlled digitally using, for example, Autocad or Revit.

- Very minimal production time on construction.

- Completely flat product.

- Efficient double meander pipe course.

- Extremely suitable for prefab (concrete) construction, circular construction systems, ready-made floors.

- Can be constructed with minimal supplies.

What are the general benefits of underfloor heating/cooling?

- No more wall elements (radiators/convectors) required, maximum space utilization.

- Less/no swirling dust in the home.

- Good combination with low temperature generation systems.

- System suitable for both heating and cooling (top cooling).

- Energy efficient.

- Comfortable indoor climate, although every person has their own comfort experience.

What are the minimum requirements?

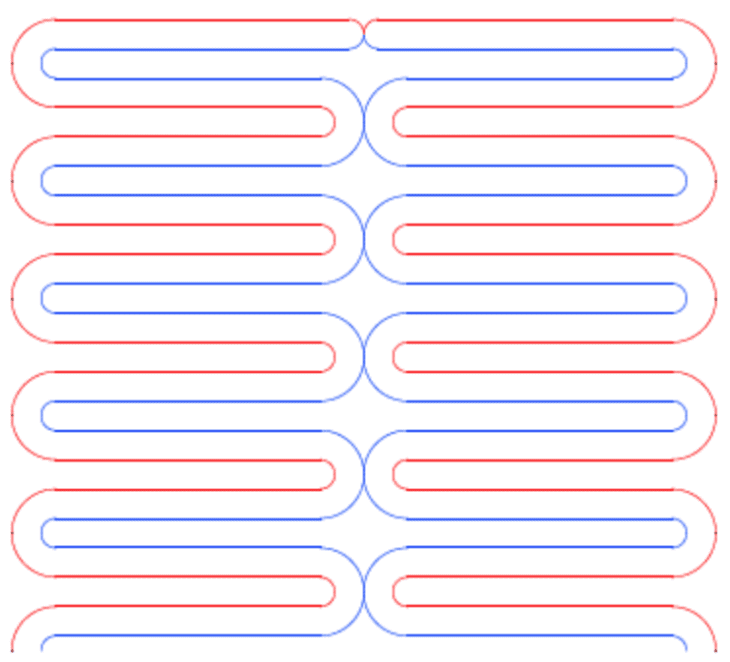

What is a double meander installation pattern?

By applying a double meander pattern, just like with the volute pattern, for example, an optimal distribution of supply and return heat takes place. Because the supply and return run alternately (every two turns) through the floor field, heat is optimally and evenly distributed.

Optimal heat distribution double meander pattern (Red=Supply Blue=Return)

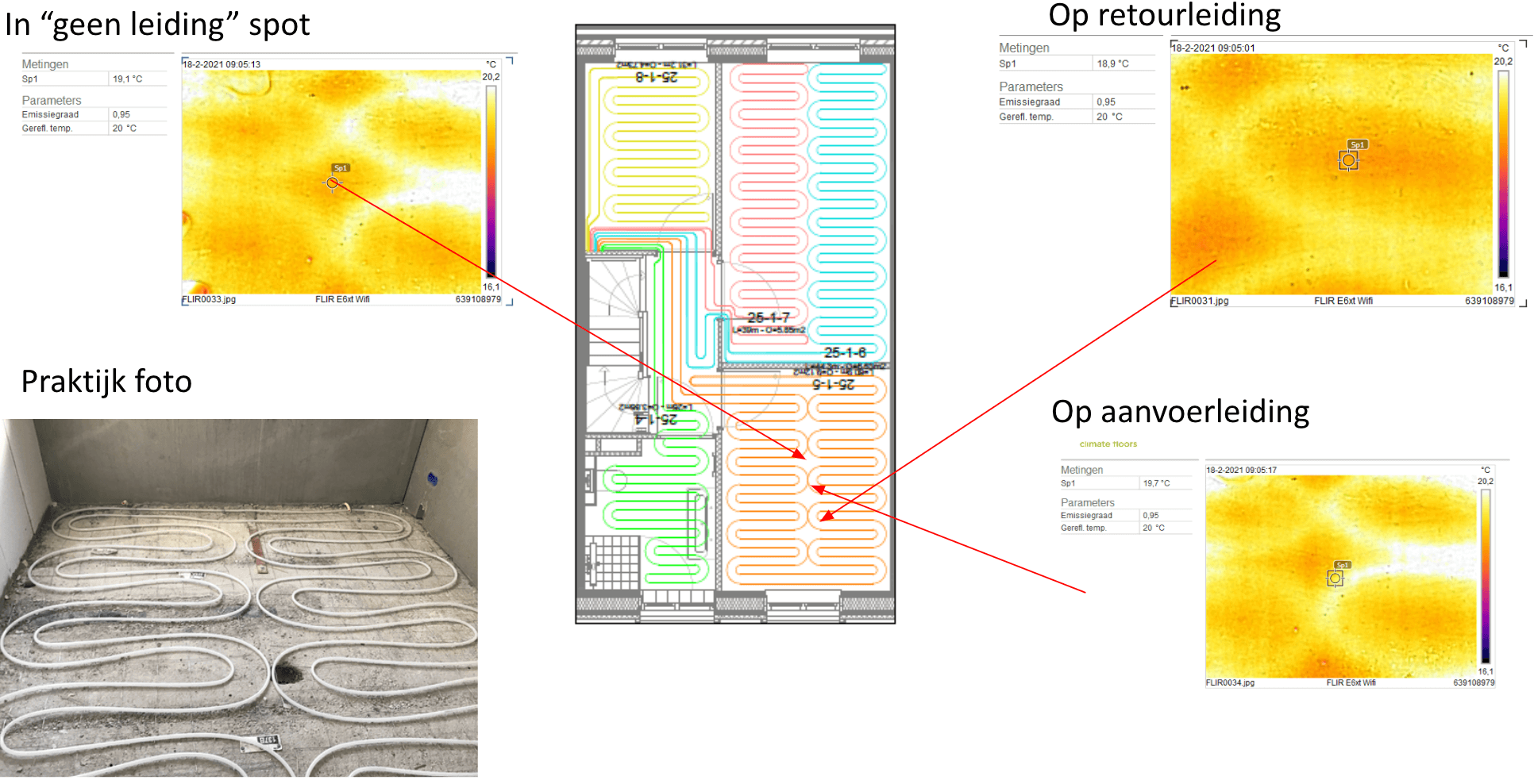

Does double meander actually provide an even heat distribution?

The answer to this is YES!

Underfloor heating is “mass” heating, which means that the entire building “mass” in the space to be heated will eventually assume the most even temperature possible, if properly constructed.

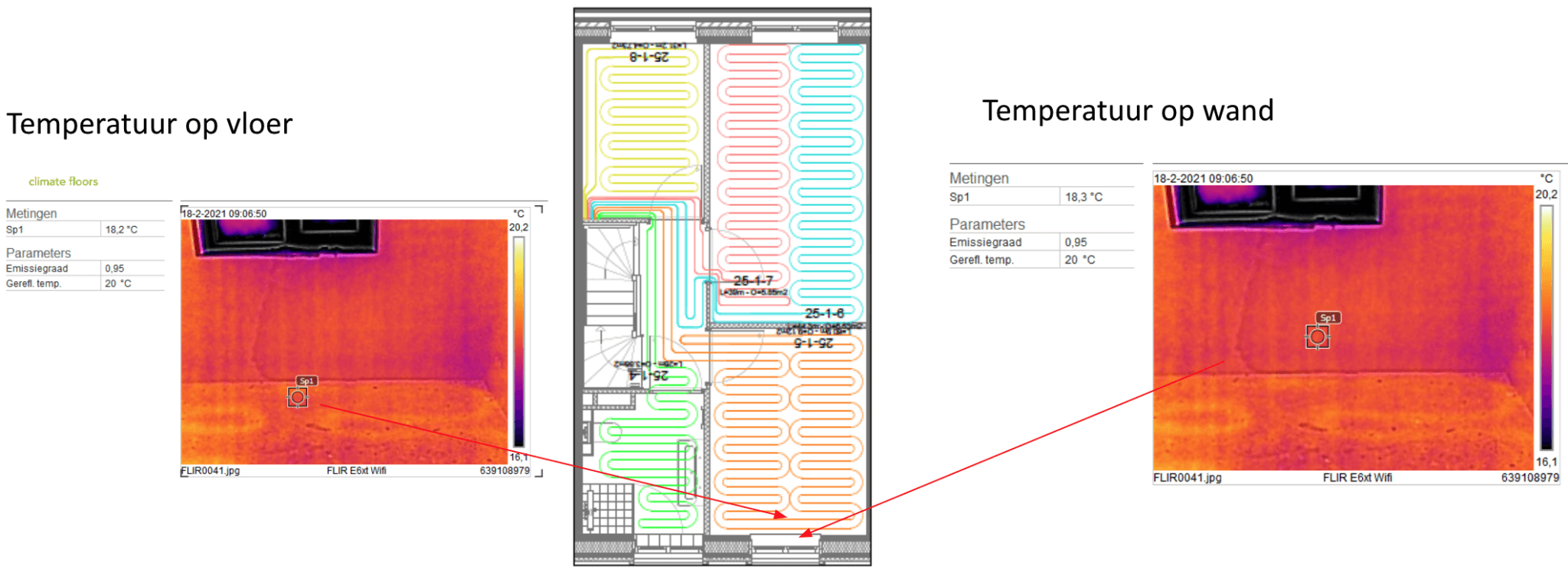

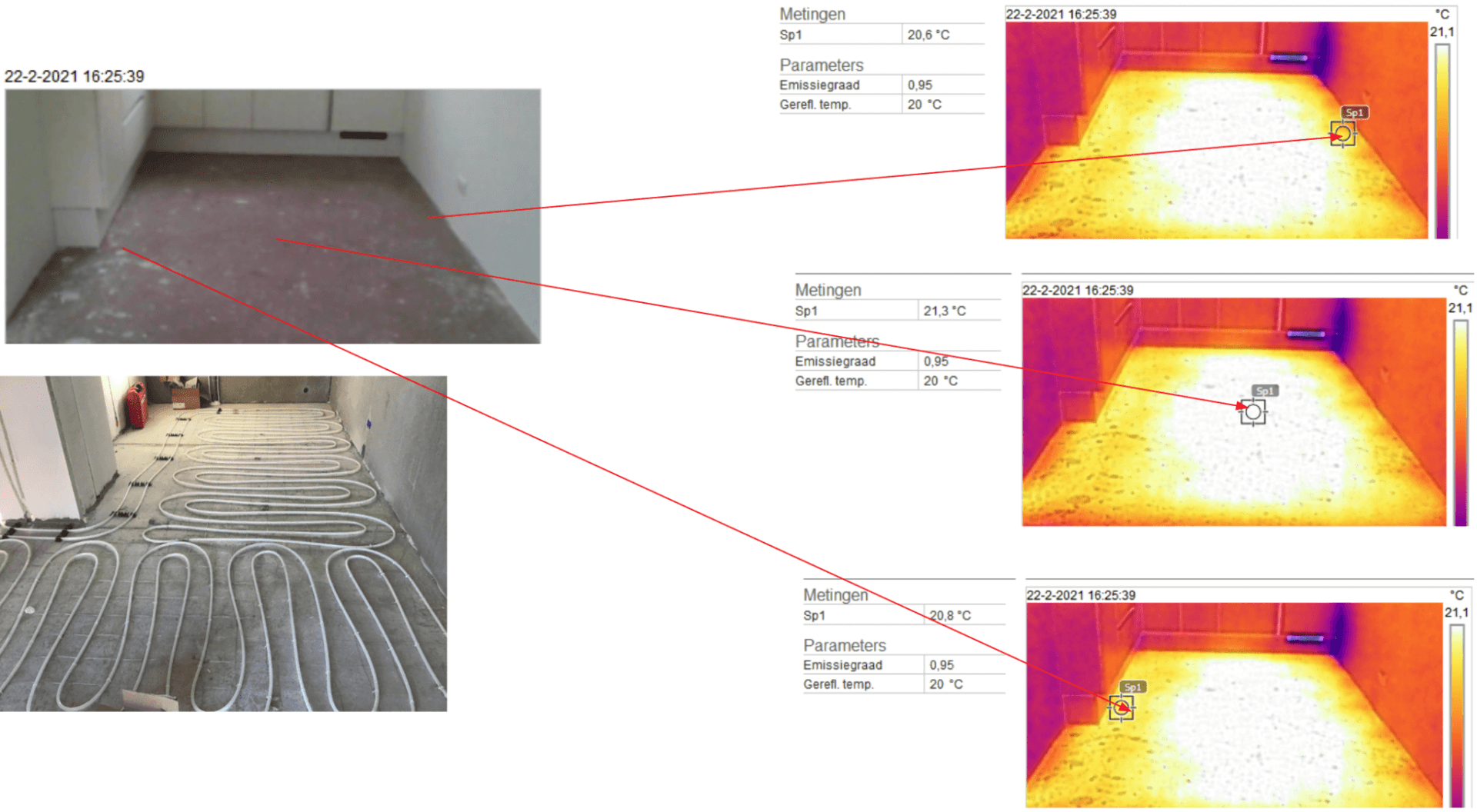

The images below show this supported by thermal images of a system we installed.

This shows that the floor has an even temperature after the system has been in operation for some time.

The remaining mass, such as rising walls, also assume the room temperature over time.

Are the pipes close enough together at a center to center of 150mm?

When developing prefab/modular solutions, standard choices are made that ensure that the solution is suitable for most of the application area (95%). One of these standard choices we make is the extension distance from center to center. 150mm.

Naturally we look at the suitability per project, but in general it can be said;

Average heat loss in a home with WTW and an RC of 4.5/5m2 K/W is approximately 35 watts per m2

Average heat loss in a home with System C and an RC of 4.5/5 m2 K/W is 40/45 watts per m2

The power to be delivered at a heating curve of 35°C/30°C is 64 watts per m2 (room temperature 20°C).

In a heat pump home, at least 50% more capacity is quickly installed than is necessary for this extension distance.

In district heating projects (higher heating curve) this is quickly 100% or (much) more.

Applying too much power has no positive effects on the comfort experience of the system.

Does laying pipes closer together help to prevent cold drafts?

As already mentioned in the previous question, with an installation distance of 150mm, in most cases pipes are already closer together than the minimum installation distance to be calculated in accordance with ISSO 49.

In order to answer the question properly, we first have to identify which types of cold trap there are. We roughly distinguish two types of “cold trap” in homes:

- Cold fall through windows.

- Cold drop through ventilation grilles in the facade (system C ventilation).

In the following questions we will discuss both cold trap types.

Does laying pipes closer together help prevent cold drafts through windows?

Clients sometimes request a compacted strip of underfloor heating near windows and doors. However, because we already provide more even heating capacity, it is not necessary to bring pipes further together than the standard installation distance from center to center of 150 mm. This is also substantiated with the example calculation below.

U value HR++ Glass= approx. 1.2 W/m2K

Heat loss per m2 of window= approximately 40 W/m2

High frame in home= 2m

Heat loss high window (750mm wide) = 60 watts (at –10ºC outside temperature)

The heat loss from the window and conditions taken in the above calculation can be more than adequately covered by the existing 2m2 underfloor heating. In addition, cold fall cannot be compensated for by radiant heat, see further explanation in question 3.2.

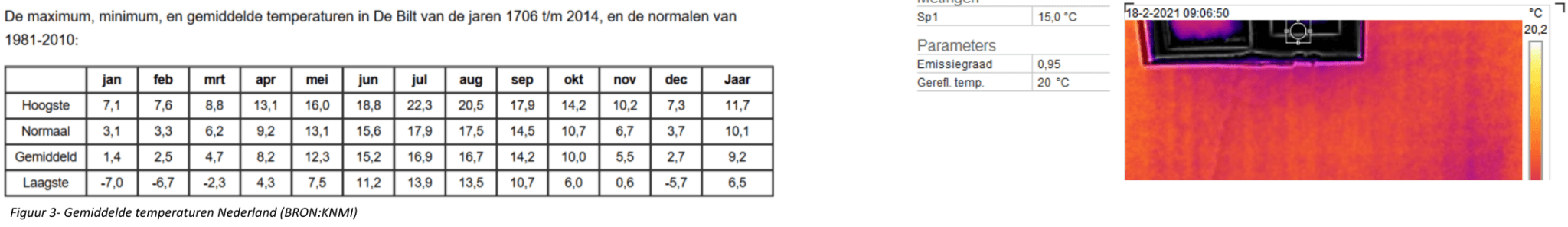

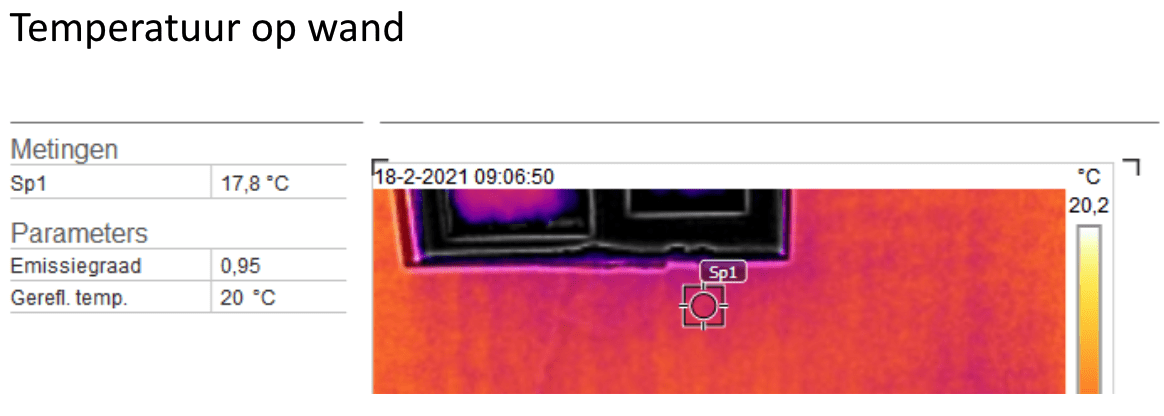

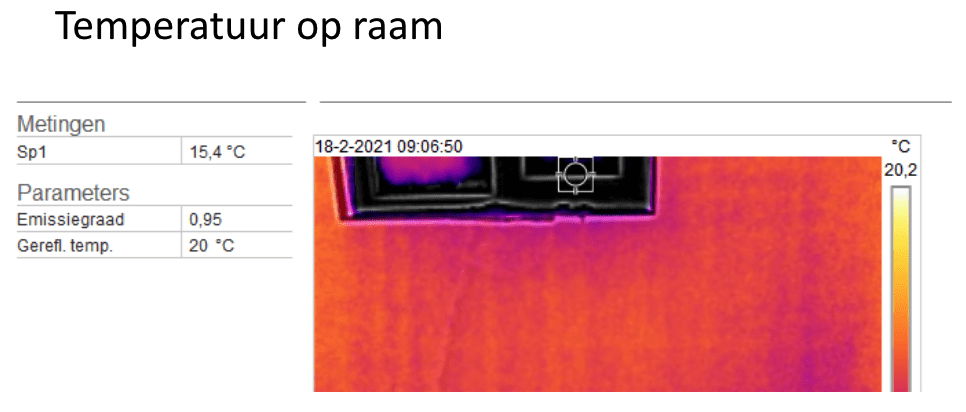

It should be said that the heat loss has been determined at a very unfavorable outside temperature (-10°C), which deviates far from average outside temperatures (see table below). In practice, it appears that the temperature of the window on the inside is a maximum of 2-4° C lower than the other construction temperature.

The ISSO 49 Quality Requirements for Floor and Wall Heating and Floor and Wall Cooling (2004) recommends laying the hoses closer together at window and door openings than the calculated installation distance. Contemporary calculated moving distance for EPC 0.4 homes is often 250/300mm center to center. We meet this requirement with center to center 150mm. Of course, we will always look at and assess this per project, because there is an exception for every rule.

Does laying pipes closer together help prevent cold drop through ventilation grilles in the facade?

Sometimes a home is still equipped with ventilation grilles in the windows (system C ventilation). In that case, cold outside air flows in to refresh the indoor air. In other words, ventilation air flows into the home at the prevailing outside temperature, which can lead to local discomfort. In a normal winter month this is easily 15°C colder than the room temperature.

This form of draught/cold trap EXPERIENCE cannot under any circumstances be solved with the underfloor heating system, not even by placing hoses against each other as tightly as possible.

An underfloor heating system heats the floor by means of heat radiation (radiation). Because the floor is heated at a low temperature and, as shown in the previous pages, has an even surface temperature, there is little to no convection.

In order to heat cold air flows, a system is always required that ensures mixing of warm and cold air particles through convection.

We therefore always recommend that, with regard to the prevention of cold trap complaints caused by ventilation grilles, you carefully look at any additional required facilities through radiation or convection. Cold air should be prevented from being supplied, for example through grilles in combination with an underfloor heating system. Such complaints usually do not occur with ventilation system D (mechanical supply and exhaust of air).

Does laying pipes closer together help to prevent cold drafts? (conclusion)

With the currently used low temperature systems, hot water is usually transported through the heating system only a few times per day. It is therefore very questionable whether this happens at those times when the end user/consumer experiences any cold symptoms.

As explained per situation, laying pipes closer together does not have the desired effect.

Shouldn’t the system be installed at a center point of 100mm because cooling is taking place?

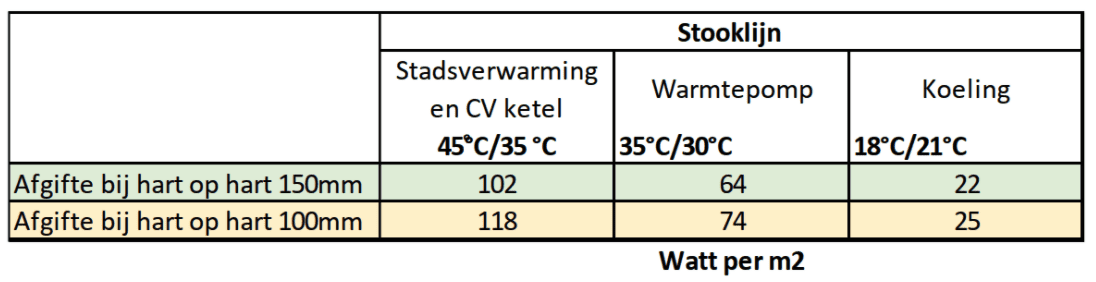

The table below shows the output of underfloor heating and cooling for the most common heating curves and associated generation systems.

Figure 2 Indicative number of underfloor heating output per m2 (assuming screed floor 60mm without intermediate insulation, stone-like or PVC floor finish)

On the cooling side, installing center to center 150mm compared to center to center 100mm has a slightly lower absorption per m2 of cooling capacity. However, this difference is marginal (on average 0.2-0.5°C per m2 of floor).

Creating an installation distance of 100mm center to center to increase the cooling capacity will have an almost negligible effect.

Links are used in the VIDALCO system, is this responsible?

We work with prefabricated modules, which means that the system is largely manufactured by a robot and only needs to be connected/connected to the distributor on the construction site.

These couplings are made using specially tested and certified materials. We use a certified piping system with associated press couplings. These couplings have all the necessary approvals and certificates and are guaranteed by the manufacturer to ensure correct operation and service life. Pipes are always pressed off a floor before pouring to definitively rule out any leakage.

The use of connections in an underfloor heating system is something that people are not used to in the “traditional” underfloor heating market. In contrast, couplings in gas, water and radiator installations are generally accepted and frequently used. When developing new systems, different product choices sometimes have to be made. Applying links in the system is one of them.

Technically, there is no objection to using couplings, provided they have been installed properly and by a skilled person.

Which type of floor finish is suitable for underfloor heating/cooling?

In general it can be said that the lower the thermal resistance of a floor, the better it is in combination with a floor delivery system. We therefore recommend choosing a floor with a maximum thermal resistance (RC) of 0.05 m².K/W.

If the heat output of your future floor finish is higher, this does not have to be a problem. But it is wise to have us or another expert calculate this for you.

The supplier of your future floor finishing can provide you with good advice regarding the suitability of this floor in combination with a floor delivery system.

Does VIDALCO have a heating protocol for commissioning the floor heating system?

The heating of the underfloor heating system should always be done in close consultation with the supplier of your finished floor. This specialist party knows exactly what the optimal method of heating your floor is, so that it will not cause any imperfections in the quality of your floor.

For this reason, we do not make a standard heating protocol available online. If desired, we have a standard heating protocol available for our customers. You can request this from your VIDALCO contact person.

Advice to future users of underfloor heating and cooling systems in new buildings.

In current new-build homes and buildings, there is only a limited heat demand due to the high-quality shell. For this reason, the underfloor heating system will largely not be in operation.

Energetically this is of course very positive. However, this does mean that the “warm feet experience” of old underfloor heating systems is no longer available. Sustainable generation (e.g. heat pump projects) also uses heating at a very low temperature, which makes the pipes in the floor less noticeable at all. The system mainly ensures that the entire building mass has an even internal temperature.

Of course, the method of heating can of course be taken into account by fine-tuning control technology based on presence (raising the thermostat in the evening), but this is not recommended from an energetic point of view. We recommend that you always leave the system at the same temperature per room as much as possible.

We advise our clients to communicate this with residents at all times.